Implementation of standardization procedures

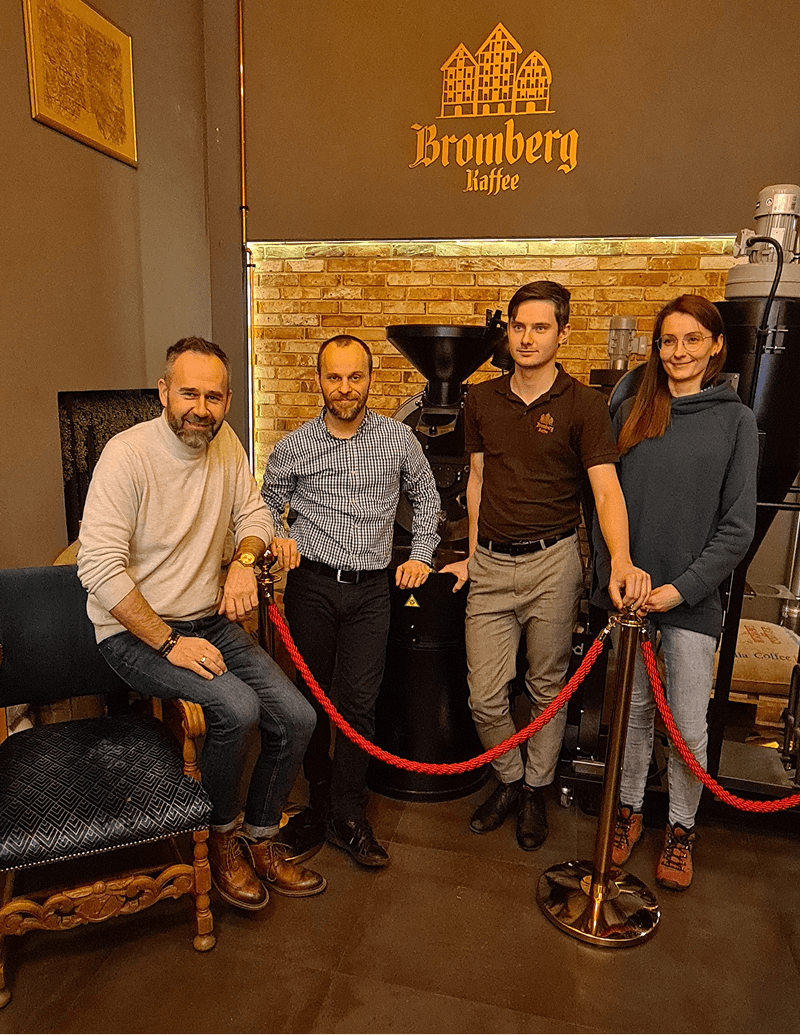

We began our work with a detailed audit of the existing coffee roasting processes and quality control methods used at Bromberg Cafe.

We then introduced:

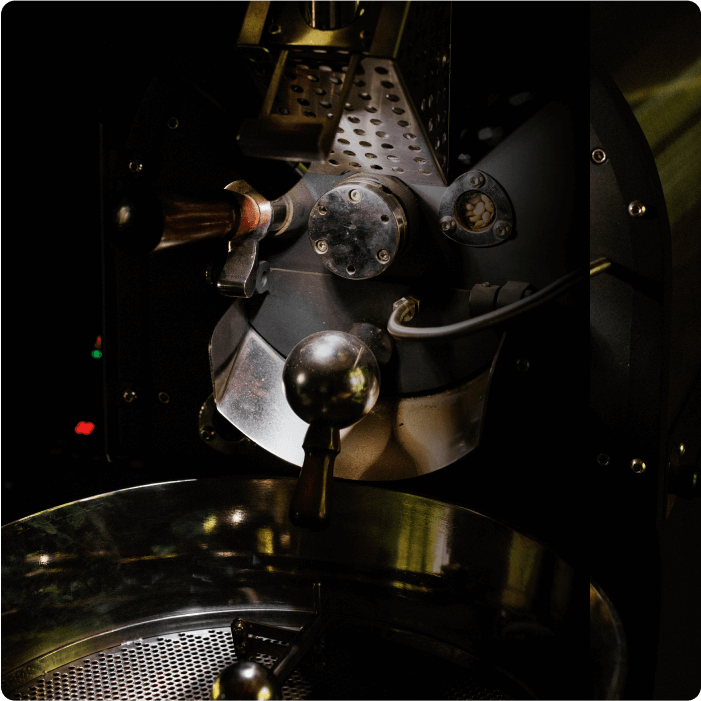

- Standardization of roasting procedures — we developed individual roasting profiles for each type of coffee to achieve repeatable results,

- Implementation of a colorimeter for objective assessment of roasted bean colour as an indicator of roast level,

- A documentation system for each roast — we introduced production sheets allowing the recording of parameters for every process,

- Development of internal coffee sensory evaluation sheets, which facilitated ongoing quality control and the detection of flavour differences.